45 Degree Pipe Miter Template

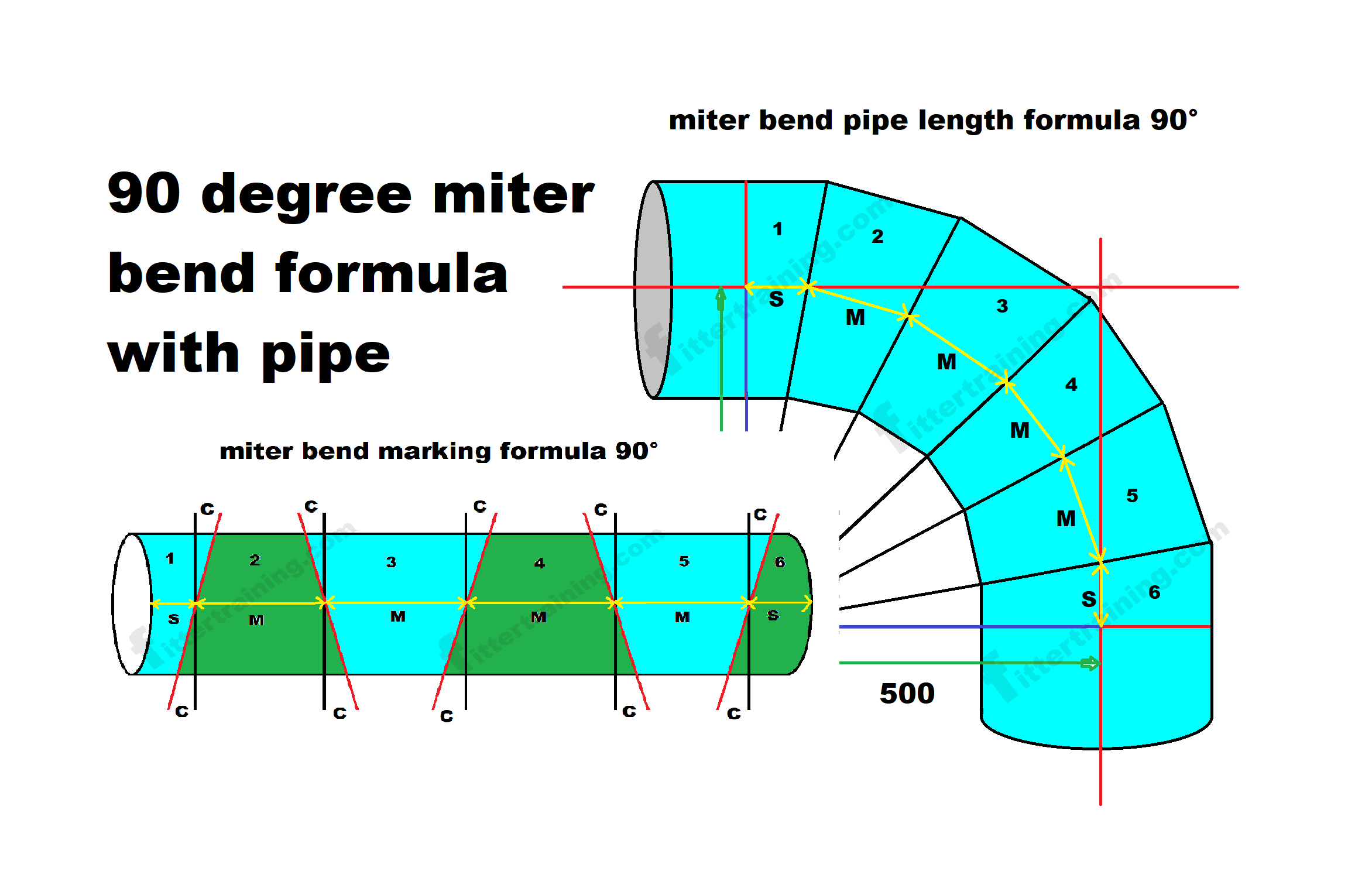

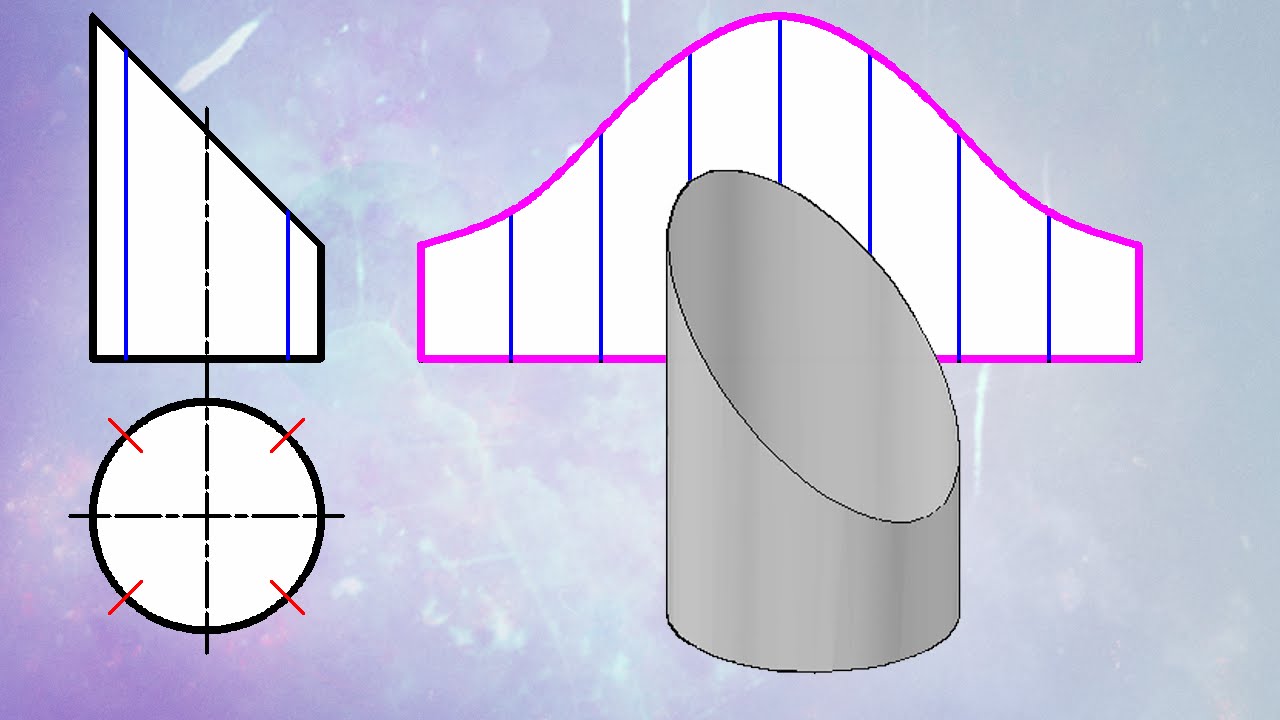

45 Degree Pipe Miter Template - Optionally “mitered”, which means it is truncated at an angle. 17m views 1 year ago #pipenotching #pipecutting. Web here is a brief example of making a pipe template using parallel line development. Make a sketch on the plane that runs through the center of the pipe. Web first video dedicated to the pipe #template #layout. Simply rub the glued surfaces together and hold them tightly on a. Web for larger pipes, or if you don't have a miter saw handy, print templates at 100% printer scale, cut and wrap around pipe to mark the miter cut. Web cylinder (mitered) diameter height twist bottom top tube, pipe, cylinder or toilet roll core. Pipe tube at angle through sheeting section diagram 1. 90° 80° 70° 60° 50° 40° 30°. On the end you want the miter, just draw the 45 degree angle and. Web manual marking of a profile pipe can lead to a huge error. Web here is a brief example of making a pipe template using parallel line development. Here is how i do it: Pipe tube at angle through sheeting section diagram 1. Here is how i do it: Make a sketch on the plane that runs through the center of the pipe. On the end you want the miter, just draw the 45 degree angle and. The best way out of this situation is to make a template for the same profile of a larger diameter. I mark in black the trace. Web first video dedicated to the pipe #template #layout. Web cylinder (mitered) diameter height twist bottom top tube, pipe, cylinder or toilet roll core. Optionally “mitered”, which means it is truncated at an angle. And let's go for the cutting, i made a test with a metal tube of 42mm and another of. Check plot points to calculate. Web 170° 160° 150° 140° 130° 120° 110° 100°. Web you can also 'poster print' to multiple smaller pages and assemble to form full template image. Check plot points to calculate. 17m views 1 year ago #pipenotching #pipecutting. Here is how i do it: I mark in black the trace on the tube receiver by plating the inserted tube. Web for larger pipes, or if you don't have a miter saw handy, print templates at 100% printer scale, cut and wrap around pipe to mark the miter cut. Web here is a brief example of making a pipe template using parallel line development. Web. Web manual marking of a profile pipe can lead to a huge error. .1 minimum, 10 maximum (2 / 200mm) wall thickness must be greater than zero. 15° 20° 25° 30° 35° 40° 45°. Web round pipe cutting idea // 45 degree angle cutting. Here is how i do it: And let's go for the cutting, i made a test with a metal tube of 42mm and another of. .1 minimum, 10 maximum (2 / 200mm) wall thickness must be greater than zero. Check plot points to calculate. Web round pipe cutting idea // 45 degree angle cutting. Simply rub the glued surfaces together and hold them tightly on a. On the end you want the miter, just draw the 45 degree angle and. 90° 80° 70° 60° 50° 40° 30°. All inch inputs and dimensions are actual physical finished sizes (unless otherwise noted) ? Web manual marking of a profile pipe can lead to a huge error. Web for larger pipes, or if you don't have a miter saw. Side angle 70° base diameter height rotate ↔. Pipe tube at angle through sheeting section diagram 1. Web here is a brief example of making a pipe template using parallel line development. For larger pipes, or if you don't have a miter saw handy, print templates at 100% printer scale, cut and. Optionally “mitered”, which means it is truncated at. On the end you want the miter, just draw the 45 degree angle and. Web you can also 'poster print' to multiple smaller pages and assemble to form full template image. Web manual marking of a profile pipe can lead to a huge error. The #development of a #cylindrical ferrule cut by a plane oblique to its axis is one. 90° 80° 70° 60° 50° 40° 30°. And let's go for the cutting, i made a test with a metal tube of 42mm and another of. Pipe tube at angle through sheeting section diagram 1. Web here is a brief example of making a pipe template using parallel line development. The #development of a #cylindrical ferrule cut by a plane oblique to its axis is one of the fundamental paths that. Web first video dedicated to the pipe #template #layout. Web you can also 'poster print' to multiple smaller pages and assemble to form full template image. Simply rub the glued surfaces together and hold them tightly on a. Web manual marking of a profile pipe can lead to a huge error. Optionally “mitered”, which means it is truncated at an angle. 15° 20° 25° 30° 35° 40° 45°. 17m views 1 year ago #pipenotching #pipecutting. All inch inputs and dimensions are actual physical finished sizes (unless otherwise noted) ? Web 170° 160° 150° 140° 130° 120° 110° 100°. .1 minimum, 10 maximum (2 / 200mm) wall thickness must be greater than zero. 1 ° 2 ° 5 ° 10 °. On the end you want the miter, just draw the 45 degree angle and. Check plot points to calculate. The best way out of this situation is to make a template for the same profile of a larger diameter. For larger pipes, or if you don't have a miter saw handy, print templates at 100% printer scale, cut and. .1 minimum, 10 maximum (2 / 200mm) wall thickness must be greater than zero. Make a sketch on the plane that runs through the center of the pipe. Pipe tube at angle through sheeting section diagram 1. 90° 80° 70° 60° 50° 40° 30°. The #development of a #cylindrical ferrule cut by a plane oblique to its axis is one of the fundamental paths that. Check plot points to calculate. 15° 20° 25° 30° 35° 40° 45°. Web manual marking of a profile pipe can lead to a huge error. Web first video dedicated to the pipe #template #layout. The best way out of this situation is to make a template for the same profile of a larger diameter. And let's go for the cutting, i made a test with a metal tube of 42mm and another of. Here is how i do it: All inch inputs and dimensions are actual physical finished sizes (unless otherwise noted) ? Optionally “mitered”, which means it is truncated at an angle. Web you can also 'poster print' to multiple smaller pages and assemble to form full template image. 17m views 1 year ago #pipenotching #pipecutting.90 degree miter bend formula with pipe to type Fitter training

Miter Elbow or Miter Bend Design Calculations Make Piping Easy

Template to miter pipe Pipe template layout YouTube

pipe miter cut elbow 45° degree 2"/ 3"/ 4"/ 6"/ 8"/ 10" with PDF chart

pipe miter cut elbow 45° degree 2"/ 3"/ 4"/ 6"/ 8"/ 10" with PDF chart

pipe miter cut elbow 60° degree 28" 30" 32" 34" with PDF chart

Watch Template to miter pipe Pipe template layout Part 1 Prime Video

pipe miter cut elbow with PDF chart / 60" 90° degree

The manaul method for designing a pipe to pipe branch ?!! Pipelines

Miter Elbow or Miter Bend Design Calculations Make Piping Easy

On The End You Want The Miter, Just Draw The 45 Degree Angle And.

Web Cylinder (Mitered) Diameter Height Twist Bottom Top Tube, Pipe, Cylinder Or Toilet Roll Core.

Web For Larger Pipes, Or If You Don't Have A Miter Saw Handy, Print Templates At 100% Printer Scale, Cut And Wrap Around Pipe To Mark The Miter Cut.

Side Angle 70° Base Diameter Height Rotate ↔.

Related Post: